Gas separation membranes are advanced materials designed to selectively separate gases from mixed streams, offering highly efficient and sustainable solutions for industries that require gas purification, recovery, and filtration. These membranes are used in a range of applications, including natural gas processing, air separation, carbon capture, and hydrogen production. By utilizing properties such as pore size and chemical selectivity, gas separation membranes allow for the targeted separation of gases, providing a more energy-efficient and environmentally friendly alternative to traditional separation methods like cryogenic distillation or absorption. As industries and governments aim to reduce emissions and improve process efficiencies, gas separation membranes are gaining recognition for their potential to enable cleaner, more sustainable operations.

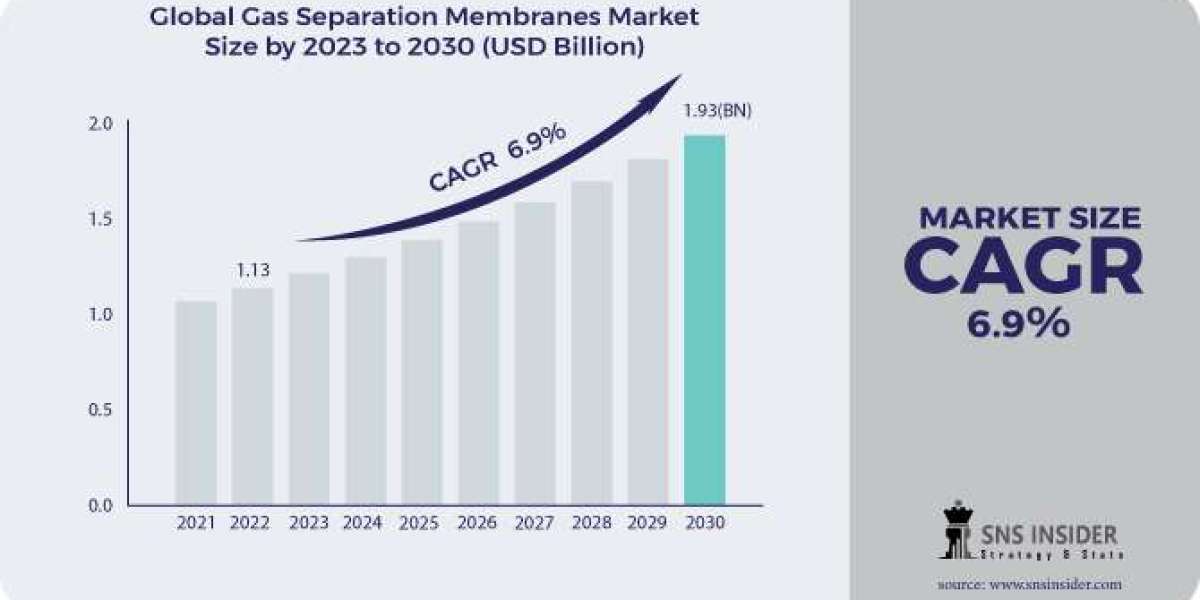

The Gas Separation Membranes Market Size was valued at USD 1.13 billion in 2022, and expected to reach USD 1.93 billion by 2030, and grow at a CAGR of 6.9% over the forecast period 2023-2030.

Future Scope

The future of gas separation membranes is closely tied to the growing emphasis on sustainability and the transition toward a circular economy. As environmental regulations tighten, industries are increasingly turning to membrane technology for applications such as carbon dioxide capture, natural gas purification, and the production of high-purity hydrogen. Innovations in membrane materials, such as the development of advanced polymers, metal-organic frameworks (MOFs), and graphene oxide membranes, are expected to further enhance separation performance and expand the scope of applications. Furthermore, the integration of gas separation membranes into carbon capture and storage (CCS) systems will play a crucial role in meeting global emissions reduction targets, making them indispensable in achieving climate goals.

Emerging Trends

Emerging trends in the gas separation membranes market include the development of more efficient and durable membrane materials, which can operate under harsh industrial conditions. Advances in membrane fabrication technologies, such as the use of 3D printing and nanostructuring, are making it possible to create membranes with superior performance characteristics. Another trend is the integration of gas separation membranes with renewable energy systems, such as biogas purification and hydrogen production, to support the transition to a low-carbon economy. Additionally, the rise of digital monitoring and control technologies for membrane filtration systems is enabling real-time performance optimization, improving efficiency, and reducing operational costs.

Drivers

The key drivers of the gas separation membranes market are the need for more efficient and sustainable separation technologies in industries such as natural gas processing, petrochemicals, and environmental protection. Stricter environmental regulations and the growing focus on reducing carbon emissions are also pushing industries toward adopting cleaner and more energy-efficient technologies. The increasing demand for hydrogen as a clean fuel source is driving innovation in membrane technologies for hydrogen purification and production. Additionally, the rising adoption of biogas as a renewable energy source is contributing to the growth of the gas separation membrane market, as these membranes are used for biogas upgrading.

Restraints

Despite the promising potential of gas separation membranes, several challenges remain. The high initial cost of membrane systems and the complexity of scaling up membrane processes for large industrial applications can be barriers to widespread adoption. Additionally, membrane fouling, which occurs when contaminants accumulate on the surface of the membrane, can reduce performance and increase maintenance costs. Developing membranes with higher resistance to fouling and longer lifespans remains a key area of research. Moreover, the need for specialized infrastructure to support membrane filtration systems in certain industries, such as carbon capture and storage, can limit adoption in some regions or sectors.

Key Points

· Gas separation membranes are used in applications such as gas purification, natural gas processing, and carbon capture.

· The future scope includes the development of advanced materials like polymers and graphene, as well as integration with renewable energy systems.

· Emerging trends include innovations in membrane materials, fabrication technologies, and digital monitoring for optimized performance.

· Drivers include stricter environmental regulations, the demand for hydrogen, and the need for sustainable gas separation technologies.

· Restraints involve high initial costs, membrane fouling, and the need for specialized infrastructure.

Get Free Sample Copy @ https://www.snsinsider.com/sample-request/1804

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)