In the realm of industrial lighting, IP65 waterproof LED lighting for manufacturing facilities has emerged as a critical component for ensuring safety and efficiency. But what does the IP65 rating signify, and why is it particularly important in manufacturing environments? This article delves into the significance of IP65 ratings and the advantages of using waterproof LED lighting in industrial settings.

What is IP65 Rating?

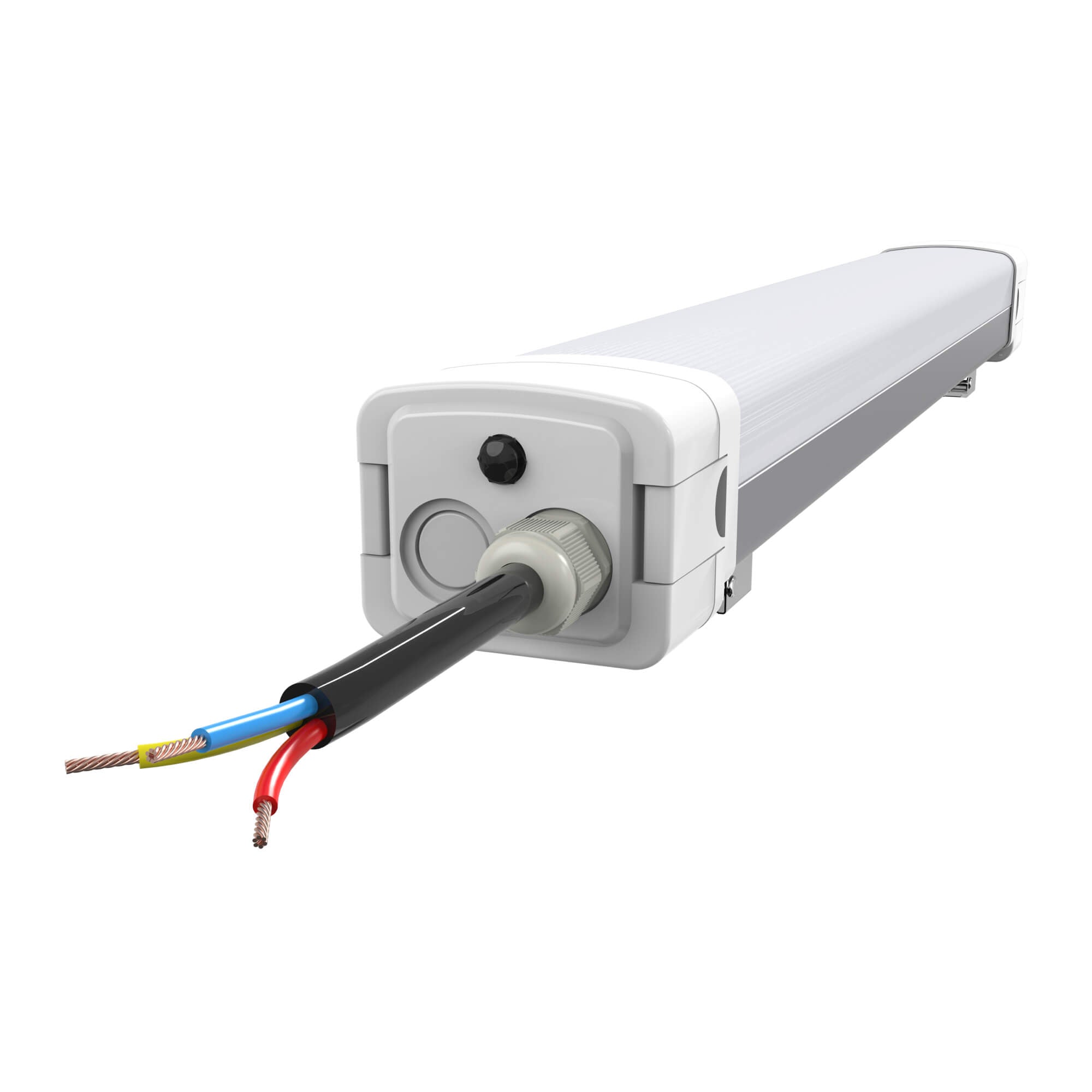

The IP (Ingress Protection) rating is a standard that defines the level of protection provided by electrical enclosures against dust and water. An IP65 rating indicates that the lighting fixture is completely dust-tight and can withstand water projected from a nozzle, making it ideal for environments where moisture and debris are prevalent.

- Dust-tight: No dust can enter the fixture, ensuring optimal performance.

- Water-resistant: Protected against water jets, making it suitable for wet locations.

Benefits of IP65 Waterproof LED Lighting for Manufacturing Facilities

Utilizing IP65 waterproof LED lighting for manufacturing facilities offers numerous benefits that enhance operational efficiency and safety:

- Durability: These fixtures are built to withstand harsh conditions, reducing maintenance costs.

- Energy Efficiency: LED technology consumes less power, leading to lower energy bills.

- Improved Visibility: Bright, consistent lighting enhances worker safety and productivity.

- Versatility: Suitable for various applications, including warehouses, production lines, and outdoor areas.

Choosing the Right IP65 Waterproof LED Lighting

When selecting IP65 waterproof LED lighting for manufacturing facilities, consider the following factors:

- Brightness: Assess the lumen output required for your specific environment.

- Color Temperature: Choose between warm or cool white light based on your facility's needs.

- Fixture Design: Ensure the design fits the layout and aesthetic of your manufacturing space.

For a comprehensive selection of industrial lighting solutions, you can explore  .

.

Conclusion

In conclusion, the importance of IP65 waterproof LED lighting for manufacturing facilities cannot be overstated. By investing in these durable and efficient lighting solutions, manufacturers can enhance safety, reduce maintenance costs, and improve overall productivity. As industries continue to evolve, ensuring that your facility is equipped with the right lighting is essential for success.