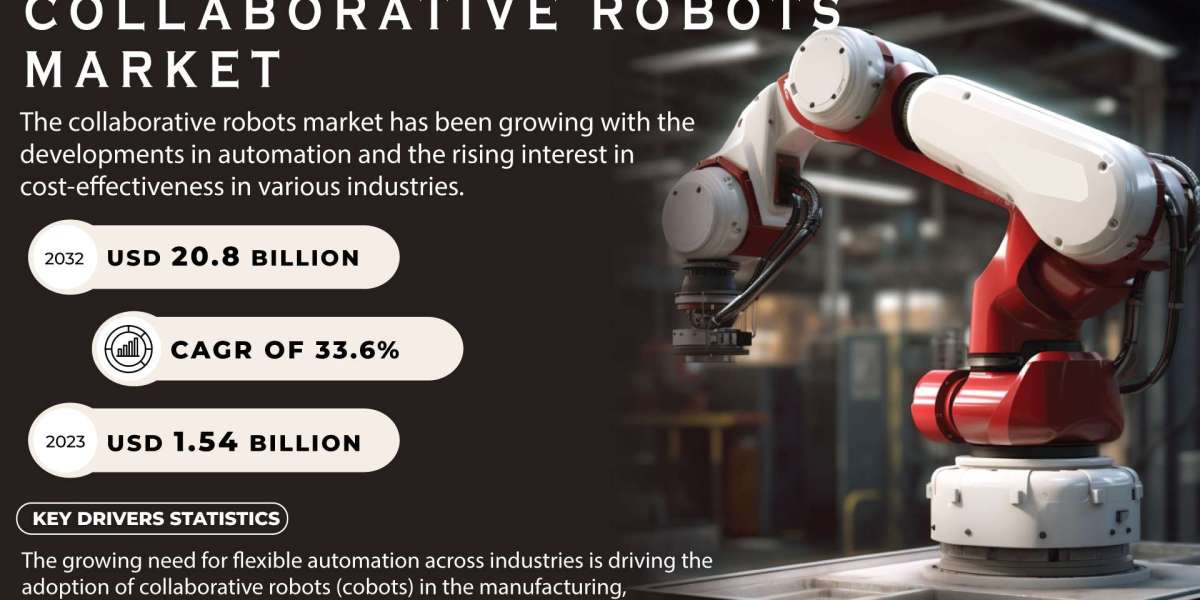

Collaborative Robots 2024

In the era of rapid technological advancement, collaborative robots, or cobots, are transforming the landscape of automation across various industries. These robots are designed to work alongside humans, enhancing productivity and efficiency while ensuring safety and ease of use. Unlike traditional industrial robots, which often operate in isolation, collaborative robots are engineered to interact safely with human workers, making them an ideal solution for a variety of applications in manufacturing, logistics, healthcare, and beyond. The Collaborative Robots Market Share has witnessed remarkable growth, with the market valued at USD 1.54 billion in 2023 and expected to grow to USD 20.8 billion by 2032, reflecting a compound annual growth rate (CAGR) of 33.6% over the forecast period from 2024 to 2032. This article explores the evolution, benefits, challenges, and future prospects of collaborative robots, highlighting their significance in modern automation.

Understanding Collaborative Robots

Collaborative robots are designed with advanced technologies that enable them to work alongside human operators without the need for safety cages or extensive safety measures. These robots are equipped with sensors, cameras, and intelligent algorithms that allow them to perceive their environment, recognize human presence, and adapt their movements accordingly. This unique capability distinguishes them from traditional robots, which typically operate in segregated environments due to safety concerns.

The development of collaborative robots is a response to the growing demand for automation solutions that can coexist with human workers. As industries face challenges such as labor shortages, increasing production demands, and the need for greater flexibility, cobots have emerged as a viable solution that combines the strengths of both humans and machines. By taking on repetitive, mundane tasks, collaborative robots free up human workers to focus on more complex and value-added activities.

Key Applications of Collaborative Robots

The versatility of collaborative robots enables them to be utilized across various sectors, each benefiting from their unique capabilities. In manufacturing, for instance, cobots can assist with assembly tasks, quality control, and material handling. They can work alongside human operators on assembly lines, performing repetitive tasks such as picking and placing components, tightening screws, or packaging finished products. By collaborating with human workers, cobots enhance efficiency, reduce cycle times, and improve overall productivity.

In the logistics and warehousing sector, collaborative robots are employed for tasks such as order picking, sorting, and palletizing. They can navigate through crowded environments, transporting goods from one location to another while interacting safely with human workers. This capability is particularly valuable in warehouses where space is limited, and the demand for quick turnaround times is high.

The healthcare industry has also embraced collaborative robots, utilizing them in various applications such as surgical assistance, rehabilitation, and patient care. Cobots can aid surgeons by providing steady hands during intricate procedures or assist healthcare professionals in lifting and transferring patients. By supporting healthcare workers, collaborative robots enhance the quality of care while reducing the risk of injury.

Benefits of Collaborative Robots

The integration of collaborative robots into various industries offers a multitude of benefits. One of the most significant advantages is increased productivity. Cobots can operate continuously without fatigue, allowing for higher output levels and reduced lead times. By automating repetitive tasks, they enable human workers to focus on more complex activities that require creativity and critical thinking.

Collaborative robots also enhance workplace safety. Unlike traditional industrial robots that pose safety risks to human workers, cobots are designed to work safely alongside people. Their advanced sensors and safety features ensure that they can detect human presence and adjust their movements accordingly. This capability reduces the risk of accidents and injuries, creating a safer work environment.

Additionally, the flexibility of collaborative robots is a noteworthy benefit. Cobots can be easily programmed and reconfigured to perform different tasks, making them suitable for various applications across industries. This adaptability allows organizations to respond quickly to changing market demands and production requirements without the need for significant investments in new equipment.

Furthermore, the deployment of collaborative robots can lead to cost savings. While the initial investment in cobots may be higher than that of traditional automation solutions, their ability to enhance productivity and reduce labor costs can result in a quick return on investment. Additionally, cobots can be integrated into existing workflows with minimal disruption, further contributing to cost efficiency.

Challenges in Implementing Collaborative Robots

Despite their numerous benefits, the implementation of collaborative robots is not without challenges. One of the primary obstacles is the initial cost of investment. While cobots can lead to long-term savings, the upfront costs associated with purchasing and integrating these robots can be a barrier for some organizations, particularly small and medium-sized enterprises.

Another challenge is the need for skilled personnel to program, operate, and maintain collaborative robots. As automation technology evolves, organizations must invest in training and upskilling their workforce to effectively utilize cobots. The lack of skilled workers in the field of robotics and automation may pose challenges for organizations seeking to implement these technologies.

Integration with existing systems can also be a hurdle. While collaborative robots are designed to be user-friendly and adaptable, ensuring seamless integration with legacy systems and processes may require careful planning and execution. Organizations must assess their current workflows and identify areas where cobots can be most effectively utilized.

Moreover, concerns related to data security and privacy can arise with the increased use of connected technologies in collaborative robots. As these robots rely on data exchange and connectivity to operate effectively, organizations must implement robust cybersecurity measures to protect sensitive information and prevent potential breaches.

The Future of Collaborative Robots

The future of collaborative robots looks promising, driven by ongoing advancements in technology and an increasing demand for automation solutions. As artificial intelligence (AI) and machine learning continue to evolve, collaborative robots will become even more intelligent and capable of handling complex tasks with greater autonomy. The integration of AI will enable cobots to learn from their experiences, improving their performance over time and allowing for more sophisticated decision-making.

The growing trend toward Industry 4.0 and the Internet of Things (IoT) will further enhance the capabilities of collaborative robots. With the ability to connect and communicate with other devices and systems, cobots will contribute to the creation of smart factories where processes are optimized, and data is leveraged for real-time decision-making.

Sustainability will also play a significant role in shaping the future of collaborative robots. As industries increasingly prioritize environmentally friendly practices, cobots can contribute to sustainable manufacturing processes by reducing waste, optimizing resource utilization, and minimizing energy consumption.

Furthermore, the collaborative robots market is expected to expand as more industries recognize the advantages of automation. From agriculture to construction, the potential applications for cobots are vast, creating new opportunities for innovation and growth.

Conclusion

Collaborative robots represent a transformative force in the realm of automation, redefining how industries approach productivity, efficiency, and safety. Their ability to work alongside human operators while enhancing productivity and reducing workplace risks makes them an attractive solution for various sectors. As the Collaborative Robots Market continues to grow, driven by technological advancements and increasing demand for automation, organizations must embrace this innovation to remain competitive in a rapidly evolving landscape. The future of collaborative robots holds immense potential, promising to revolutionize industries and create new possibilities for human-machine collaboration.

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

About Us

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Read Our Other Reports:

Fintech-as-a-Service Market Share