Laser engraving machines for sale shaft

To understand the online query trend of "Which direction is the y-axis of the laser engraving machine moving", we will first visit the basics of this topic. Laser engraving uses laser beams (very obviously) to carve or cut various materials in different patterns, for which they use two common axes, X and Y. The X-axis shows horizontal movement, or from left to right. The Y-axis, on the other hand, is vertical, or from top to bottom, and vice versa. The Z-axis is used for focusing, not for moving the laser module.

Relative to the Y-axis movement, most laser engraving machines for sale have a positive Y-axis direction toward the back of the laser cutter and a negative Y-axis direction toward the operator. However, this may not be the case for you, depending on how your machine is arranged and the software Settings you run with the hardware.

To better explain the trend query "In which direction is the Y-axis of the laser engraving machines for sale moving?", let's go further: positive Y-axis movement usually means that the laser module is moving in the direction that normally appears opposite to the operator, that is, towards the rear of the machine body. The negative Y-axis movement will be from the laser head to the operator, in the opposite direction.

Application of Y axis in laser engraving

As one might expect, both axes play a key role in helping guide the laser module to work properly and can be configured in different ways in software such as LightBurn or AI. When it comes to the Y-axis, the configurable speed, power, and precision of the Y-axis motion depends on the material type and design complexity. To better understand the problem of "Which direction is the y-axis of the laser engraving machine moving", please consider the following decomposition:

1. Speed: A slower Y-axis speed is desirable in cases where a high level of sculpting detail is required, and a faster speed is required when faster sculpting is required to complete less detailed work.

2. Power: These Settings refer to the operating distance of the laser when engraving the material on the machine bed. The higher power Settings on the X and Y axes make it easy to fuse softer materials.

3. Acceleration: Some special laser cutting machines also have the option to configure these speeds. This option in the software enables the user to set the acceleration of the Y-axis, which helps to limit the impact motion of the module. This provides smooth sculpted curves and details for your design.

This feature is very important when it comes to making complex designs. For example, when performing a multi-stage laser cutting, the machine needs to move sideways along the Y-axis appropriately to produce the desired depth impression in the final execution of the design.

Set up the laser engraving machines for sale for precise Y-axis movement.

Any original equipment manufacturer's laser engraving machine is usually set up from the "home page" position, which is usually located in the lower left corner. The position of the laser module at the beginning of the contour movement is called the Y-axis origin, which determines the vertical distance of the laser head. Not reorienting the design accordingly may cause the laser to carve your design upside down. In the software you use, always configure the design direction associated with this starting point.

Engraving problems, such as design images along the Y-axis, can be caused by incorrect Settings on the software. We always recommend checking and modifying these in the design software, depending on the right direction. Also, check that your Y-axis stopper is properly engaged so that the laser head does not move too far or too short during engraving.

conclusion

Before we conclude our views on the trend query "Which direction is the y-axis of the laser engraving machines for sale moving", we can say that the design software optimized to solve the above directional problems has greatly improved the DIY laser cutting experience.

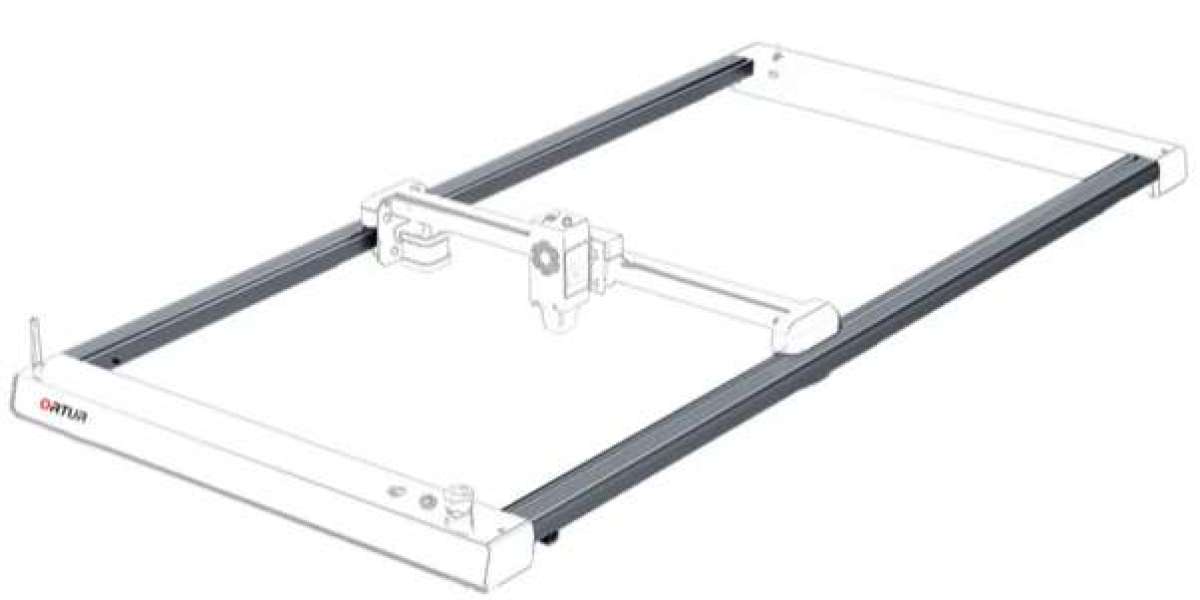

That's why we recommend using Inspiraesth, a complete laser cutting software with an Ortur LM3 laser engraving machine for sale. It provides a simple and professional choice of patterns for each sculpting stage and has a user-friendly experience to correctly configure the shaft in the sculpting design. The hardware itself is highly efficient in terms of the accuracy of the final result, thanks to its 0.01mm accuracy, next-generation motherboard, and amazing speed of 20,00mm /min, making it possible to do DIY work in a short time.

Search

Popular Posts