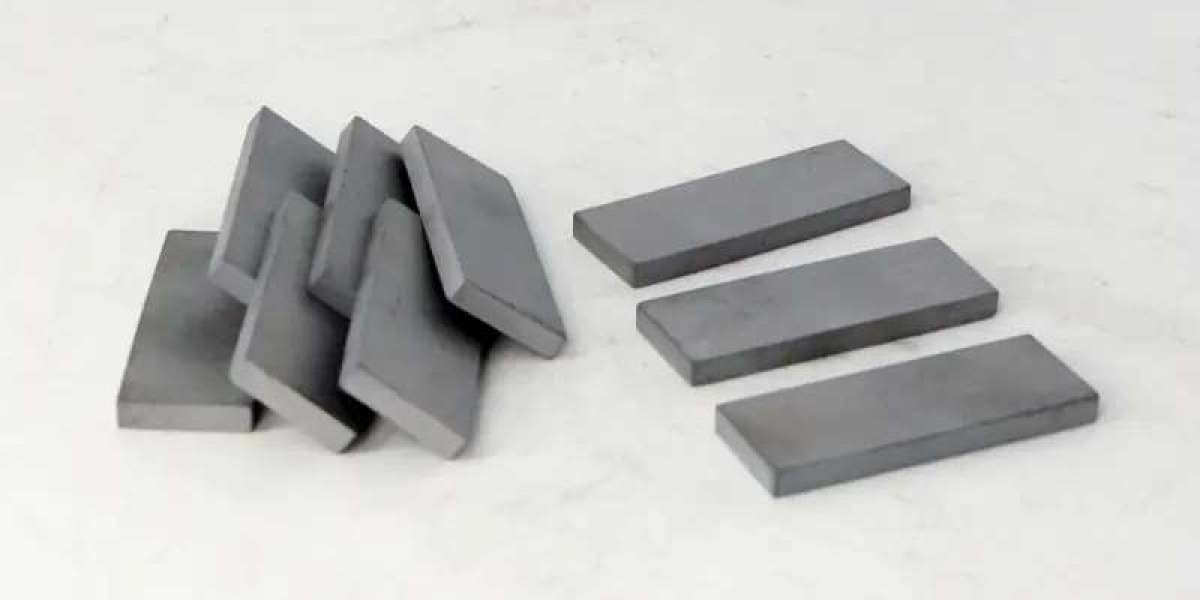

In the realm of industrial wear parts, tungsten carbide stands out for its unmatched hardness and durability. ZGJRDCC, a leading manufacturer in this field, is renowned for its innovative approach to developing tungsten carbide wear parts tailored for specialized industries. This article explores how ZGJRDCC leverages its expertise and Tungsten Carbide Wear Parts Manufacturers cutting-edge technology to deliver wear parts that meet the unique demands of various industrial sectors.

The Role of Tungsten Carbide in Specialized Industries

Tungsten carbide is a critical material in industries that require high-performance components capable of withstanding extreme conditions. Its remarkable properties make it ideal for applications where standard materials fall short:

Exceptional Hardness and Wear Resistance

Durability: Tungsten carbide's extreme hardness ensures that wear parts can endure abrasive environments and heavy loads without significant wear.

Long-Lasting Performance: Components made from tungsten carbide maintain their functionality over extended periods, reducing the need for frequent replacements.

High Temperature and Pressure Tolerance

Thermal Stability: Tungsten carbide retains its mechanical properties even at elevated temperatures, making it suitable for high-temperature applications.

Pressure Resistance: The material's resistance to deformation under high pressures ensures reliable performance in demanding conditions.

ZGJRDCC’s Innovative Approach to Tungsten Carbide Wear Parts

ZGJRDCC distinguishes itself through a commitment to innovation in tungsten carbide wear parts manufacturing. The company’s approach combines advanced technology, expert design, and customer-focused solutions:

Cutting-Edge Technology and Material Science

Advanced Material Processing: ZGJRDCC utilizes state-of-the-art sintering techniques to achieve the desired properties of tungsten carbide. This process involves precise control over temperature and pressure, ensuring a uniform and durable material.

High-Tech Machining: The company employs Computer Numerical Control (CNC) machining for creating complex geometries and precise dimensions. This technology allows for high accuracy and consistency in wear part production.

Custom Design and Engineering

Tailored Solutions: Understanding that each industry has specific needs, ZGJRDCC offers customized design services. Their engineering team works closely with clients to develop wear parts that are optimized for their particular applications.

Prototyping and Testing: Before full-scale production, ZGJRDCC creates prototypes and conducts rigorous testing. This process ensures that the wear parts meet performance standards and can handle the expected conditions.

Rigorous Quality Assurance

Real-Time Monitoring: During manufacturing, ZGJRDCC implements continuous monitoring to maintain high standards of quality. This includes checking for material consistency and dimensional accuracy.

Comprehensive Testing: Final products undergo extensive testing to verify their performance under simulated operational conditions. This thorough approach guarantees that the wear parts will perform reliably in real-world applications.

Applications in Specialized Industries

ZGJRDCC’s tungsten carbide wear parts are designed to meet the unique requirements of various specialized industries. Here are some examples:

Mining and Drilling

Drill Bits and Reamers: ZGJRDCC’s wear parts for mining and drilling equipment are engineered to endure the harsh environments of drilling operations. These parts enhance drilling efficiency and extend the life of equipment.

Construction and Earthmoving

Cutting Tools and Edges: In construction and earthmoving, ZGJRDCC provides wear parts such as cutting edges and teeth that withstand the rigorous conditions of excavation and material handling. These components are built for durability and high performance.

Oil and Gas

Exploration and Production Equipment: The company’s tungsten carbide wear parts for the oil and gas industry are designed to handle extreme pressures and temperatures. These parts are crucial for maintaining operational reliability in challenging exploration and production environments.

Commitment to Innovation and Excellence

ZGJRDCC’s commitment to innovation is reflected in its ongoing efforts to improve and expand its product offerings:

Research and Development: The company invests in research and development to stay ahead of industry trends and technological advancements. This focus ensures that ZGJRDCC continues to provide cutting-edge solutions.

Customer-Centric Approach: ZGJRDCC’s dedication to understanding and meeting client needs drives its innovation. By working closely with customers, the company delivers solutions that provide real value and address specific challenges.

Conclusion

ZGJRDCC’s innovative approach to manufacturing tungsten carbide wear parts sets it apart as a leader in the industry. By combining advanced technology, expert design, and a commitment to quality, the company delivers wear parts that excel in performance and durability. For specialized industries seeking high-performance solutions, ZGJRDCC offers unparalleled expertise and innovative products that meet the most demanding requirements.