In a strategic move towards advancing welding technology, the industry is abuzz with the introduction of the groundbreaking Advanced Industrial High Duty Mig Welding Machine. This innovative solution is poised to reshape welding practices across a spectrum of applications, reaching a new

In a strategic move towards advancing welding technology, the industry is abuzz with the introduction of the groundbreaking Advanced

Industrial High Duty Mig Welding Machine. This innovative solution is poised to reshape welding practices across a spectrum of applications, reaching a new level for efficiency and precision.

Pioneering Technological Advancements

The unveiling of the Advanced Industrial High Duty Mig Welding Machine reachs a new level in the welding industry's journey towards embracing advanced technology. Boasting a suite of advanced features, this welding marvel is designed to cater to the evolving needs of industries ranging from manufacturing and construction to shipbuilding and automotive.

Enhanced Performance Across Industries

This welding solution goes beyond conventional boundaries, promising enhanced performance in various industrial sectors. Its high-duty capabilities make it well-suited for heavy-duty fabrication, structural welding, and intricate automotive applications. Welders can now rely on this machine to deliver consistent and reliable results, irrespective of the complexity of the task at hand.

Versatility for Varied Welding Requirements

The true strength of the Advanced Industrial High Duty Mig Welding Machine lies in its versatility. Equipped with adaptable settings and controls, it seamlessly accommodates diverse welding requirements. Whether working with thin sheet metal or thick industrial components, welders now have a single, adaptable tool at their disposal, simplifying their workflows.

Precision Engineering for Good Results

Precision is the cornerstone of welding, and this welding machine places it at first. Integrated technology ensures precise control over welding parameters, meaning to high-quality welds with fewer spatter. This not only elevates the overall quality of work but also streamlines post-weld cleanup processes, optimizing time and resources.

Improved User Experience for Seamless Operation

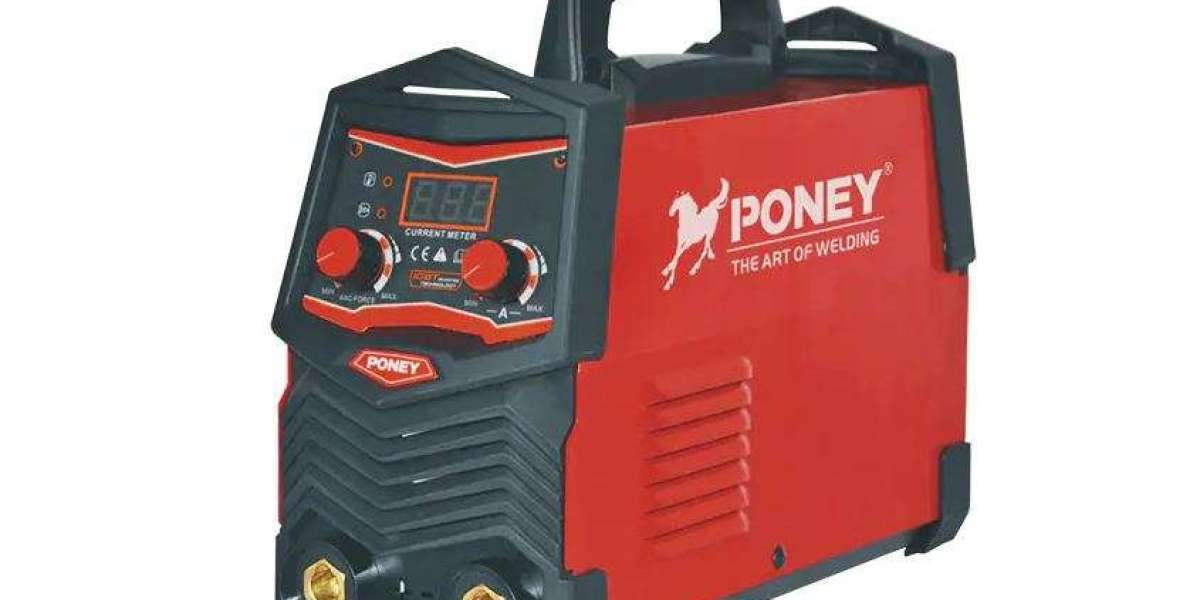

Recognizing the importance of user experience, the Advanced Industrial High Duty Mig Welding Machine is designed with an intuitive interface. Welders of all skill levels can navigate its user-friendly controls and digital display effortlessly, promoting a seamless welding experience and reducing the learning curve associated with new equipment.

Applications Across Industries

The versatility of this welding machine extends its applications across a multitude of industries. From manufacturing plants and construction sites to shipyards and automotive workshops, its adaptability positions it as a good solution for welding professionals seeking efficiency without compromising on quality.

Enhanced Safety Features for Operator Well-being

Safety remains a top priority in welding operations, and the Advanced Industrial High Duty Mig Welding Machine raises the bar with advanced safety features. From overheat protection to voltage control, these measures contribute to a secure working environment, mitigating potential hazards associated with welding processes.

The introduction of the Advanced Industrial High Duty Mig Welding Machine signals a transformative phase in the welding industry. Its incorporation of pioneering technology, versatile applications, and commitment to safety positions it as a catalyst for change. As industries evolve, this welding solution stands ready to shape the future of welding practices, ensuring efficiency, precision, and safety in equal measure. As industries embrace innovation, this welding marvel remains at the high level, evolving alongside. Adapting to emerging challenges, it continues to redefine standards, ensuring a seamless welding experience for professionals worldwide.