Dendrimers are highly branched polymers with a three-dimensional structure. They are characterized by expansive functional groups on their surface, which can be tailored to interact with specific molecules or to be used in a variety of applications. Dendrimers have attracted much attention in drug delivery (e.g., for protein drug delivery service), imaging, and materials science due to their unique structure, high monodispersity, and tunable properties. They are frequently used as nanocarriers to deliver drugs or imaging agents to specific targets in the body, as well as in the development of advanced materials with unique properties.

What is dendrimer engineering?

Dendrimer engineering focuses on tailoring the size, shape, and functionality of dendrimers to optimize their performance for specific applications. This may include controlling the branching pattern, functional groups, and overall structure of the dendrimer to achieve desired properties and functionality.

Why choose dendrimer engineering?

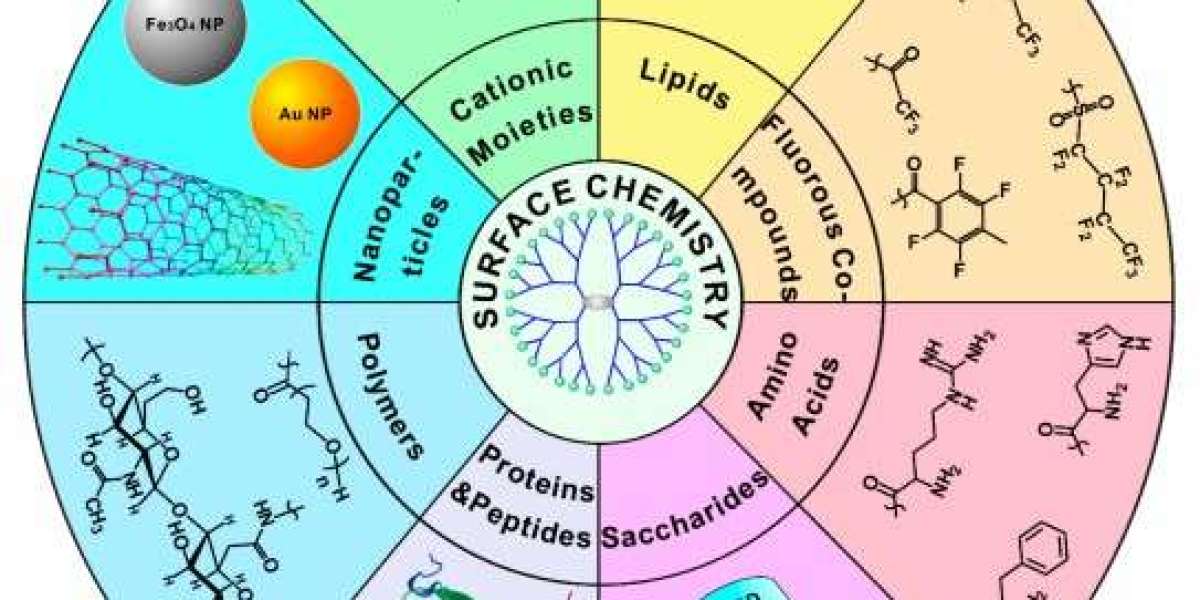

Dendritic polymers have analogous downsides to other nanomaterials, such as low transfer efficiency and poor control over drug release actions. However, dendrimer engineering can effectively compensate for these drawbacks. For illustration, functional surface modification of dendrimers is one way to address cytotoxicity. Dendrimers can be designed with specific structures and functionalities that allow precise control of their properties, such as size, shape, solubility, and stability. Dendrimers can also be designed with targeting ligands that allow them to selectively deliver drugs or imaging agents to specific cells or tissues, perfecting their effectiveness and reducing off-target effects. The designed dendrimers have strong stability and improved biocompatibility, and can be used through the design of multifunctional groups and binding sites.

Process of dendrimer engineering

In general, the dendrimer engineering process involves the design, synthesis, modification, and structural optimization of dendrimers. This process requires in-depth knowledge of their unique properties and the desired application to tailor their structure for specific applications. By systematically conforming the size, shape, surface functionality, and internal structure of dendrimers, researchers can fine-tune their properties and improve their performance in wide fields. Through careful design, dendrimers can be tailored to the specific requirements of different applications, making them flexible and powerful tools in nanotechnology.

Presently, some of the popular areas of dendrimer engineering are drug delivery (by encapsulating drugs in their internal cavities and targeting them to specific tissues or cells), imaging (e.g. MRI and PET), biomaterials (e.g. scaffolds for cell growth), gene delivery (as vectors) and sensors (as they can bind to specific molecules). These explorations are not only carried out in scientific institutions but also involve numerous CRO companies that can offer related services for researchers (e.g., dendrimer conjugation services).

In conclusion, with continued research and technological advances, dendrimers will continue to play an important role in new drug delivery systems, imaging tools, catalysts, and more. In addition, the ability to design dendrimers with different properties to meet the requirements of different industries will further boost their uptake in different fields.