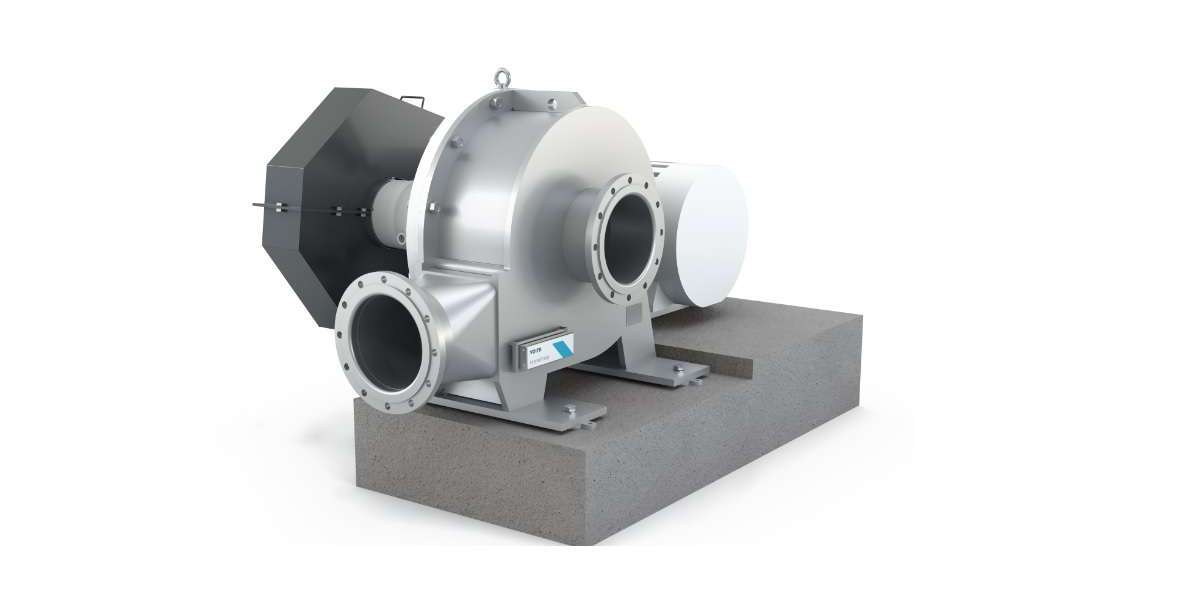

Contaminant-laden stock flows in pulping systems for recovered paper require a specialized pump to ensure reliable and largely blockage-free conveyance. The new IntensaPump, suitable for both LC and HC systems, excels at pumping critical contaminants to the next machine efficiently and effectively.

"Compared to its predecessor, the Contaminex CM, the IntensaPump offers our customers numerous benefits, including higher throughput, reduced energy requirements, lower maintenance needs, and improved runability. These advantages make the IntensaPump a valuable addition to our comprehensive BlueLine portfolio and the Intensa family," says Wolfgang Müller, Global Product Manager Pulping at Voith.

Voith's BlueLine portfolio features modern machines and products for stock preparation, characterized by efficient energy and raw material consumption, as well as gentle fiber treatment.

Technical Advancements for Customer Benefits

The IntensaPump’s advanced design allows large debris to pass easily through the pump housing. The large nozzle and housing space, along with the recessed vortex impeller, prevent clogging. A frequency converter optimizes pump speed, reducing energy consumption during discontinuous operation. During pumping pauses, sediment and wear-promoting particles settle in the horizontal nozzle, preventing further circulation within the pump housing.

"Installing the IntensaPump on our OCC 3 has significantly reduced blockages, saving us time and maintenance work. Additionally, we use less energy during operation, positively impacting our CO2 emissions and costs," says Osman Özkeser, Project Manager of the OCC 3 rebuild at Modern Karton.

Integration with Voith’s BluePulp LC System

The IntensaPump, when combined with the IntensaPulper, IntensaMaXX, and IntensaScreenDrum, forms part of Voith’s BluePulp LC system. This system is designed for minimal fiber consumption, reduced maintenance costs, lower energy consumption, and optimal runability.