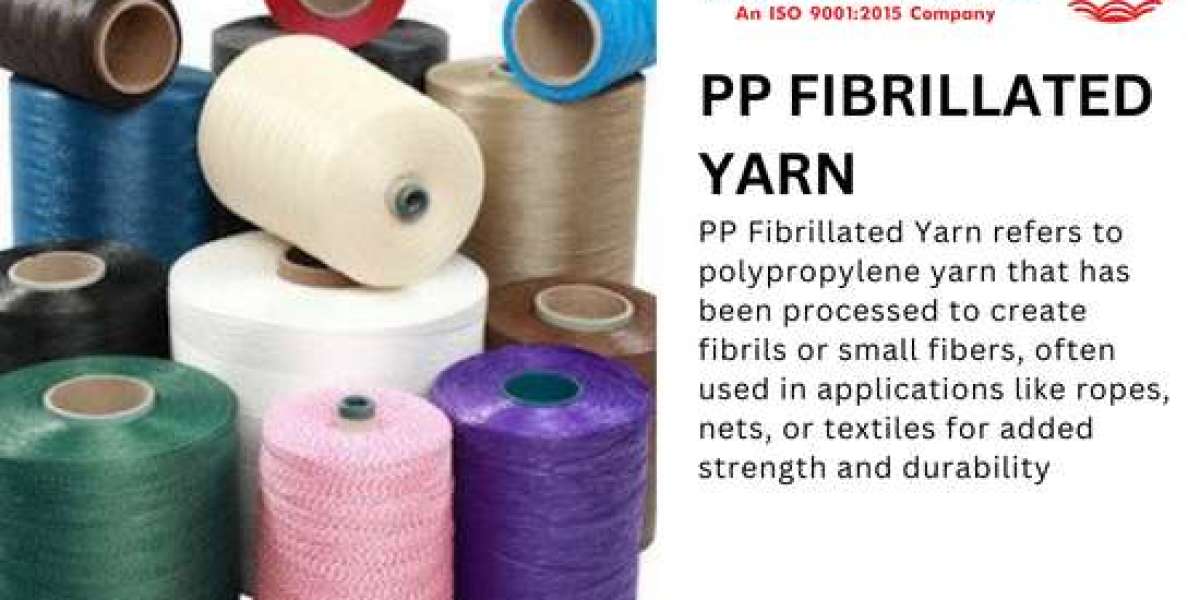

In the vast realm of textile innovation, polypropylene (PP) fibrillated yarn stands out as a remarkable creation. Its versatility, durability, and eco-friendliness have made it a sought-after material in various industries, from textiles to agriculture. In this article, we delve into the intricacies of Fibrillated Yarn Supplier in Ahmedabad, exploring its composition, applications, benefits, and frequently asked questions.

Understanding PP Fibrillated Yarn

PP fibrillated yarn is crafted from polypropylene, a thermoplastic polymer renowned for its robustness and flexibility. Through advanced manufacturing processes, polypropylene is extruded and stretched to form fine filaments, which are then mechanically fibrillated into microfibers. These microfibers possess exceptional strength and resilience, making PP fibrillated yarn an ideal choice for a myriad of applications.

Applications of PP Fibrillated Yarn

Geotextiles: Polypropylene Yarn Supplier in Ahmedabad finds extensive use in geotextile applications, where its high tensile strength and resistance to environmental factors make it indispensable for erosion control, soil stabilization, and drainage systems.

Agrotextiles: In agriculture, PP fibrillated yarn is employed in crop protection nets, shading nets, and hail nets. Its lightweight yet durable nature provides farmers with reliable solutions for safeguarding crops against adverse weather conditions and pests.

Industrial Packaging: Due to its robustness and tear resistance, PP fibrillated yarn is widely utilized in industrial packaging materials such as woven sacks, bulk bags, and tarpaulins, ensuring the safe transport and storage of goods.

Construction: PP fibrillated yarn reinforces concrete and asphalt, enhancing their strength and durability. Additionally, it is used in the production of geogrids and geomembranes for applications like road construction, landfills, and retaining walls.

Sports and Leisure: From ropes and nets for sports equipment to outdoor furniture and recreational mats, PP fibrillated yarn contributes to the production of durable and weather-resistant products for sports and leisure activities.

Benefits of PP Fibrillated Yarn

Strength and Durability: Polypropylene Yarn Manufacturers in India exhibits remarkable tensile strength and resistance to abrasion, ensuring longevity and reliability in various applications.

Lightweight: Despite its robustness, PP fibrillated yarn is lightweight, making it easy to handle and transport, thus reducing logistical costs.

Chemical Resistance: Polypropylene is inherently resistant to chemicals, acids, and alkalis, making PP fibrillated yarn suitable for use in harsh industrial environments.

UV Stability: PP fibrillated yarns are UV stabilized, maintaining their structural integrity and colorfastness even when exposed to prolonged sunlight.

Environmentally Friendly: Being recyclable and non-toxic, polypropylene contributes to sustainable practices, making PP fibrillated yarn an eco-friendly choice for various applications.

Conclusion

PP fibrillated yarn emerges as a versatile and sustainable solution across diverse industries, offering unparalleled strength, durability, and environmental compatibility. From geotextiles to agricultural nets and industrial packaging, its myriad applications underscore its significance in modern manufacturing and construction practices. As innovation continues to drive the evolution of textiles, PP fibrillated yarn remains at the forefront, paving the way for a more resilient and sustainable future.

Frequently Asked Questions (F&Q)

1. Is PP fibrillated yarn biodegradable?

No, polypropylene is not biodegradable. However, it is recyclable, contributing to a circular economy and reducing environmental impact.

2. Can PP fibrillated yarn withstand harsh weather conditions?

Yes, PP fibrillated yarn is highly resistant to UV radiation, moisture, and temperature fluctuations, making it suitable for outdoor applications in diverse climates.

3. How does PP fibrillated yarn compare to other materials like nylon or polyester?

PP fibrillated yarn offers comparable strength to materials like nylon and polyester but is often preferred for its lower cost, chemical resistance, and eco-friendliness.

4. Is PP fibrillated yarn suitable for use in contact with food products?

Yes, polypropylene is FDA-approved for food contact applications, ensuring its safety and suitability for use in packaging materials and food processing equipment.

5. Can PP fibrillated yarn be dyed or printed?

Yes, PP fibrillated yarn can be dyed or printed using conventional methods, allowing for a wide range of color options and customization possibilities.