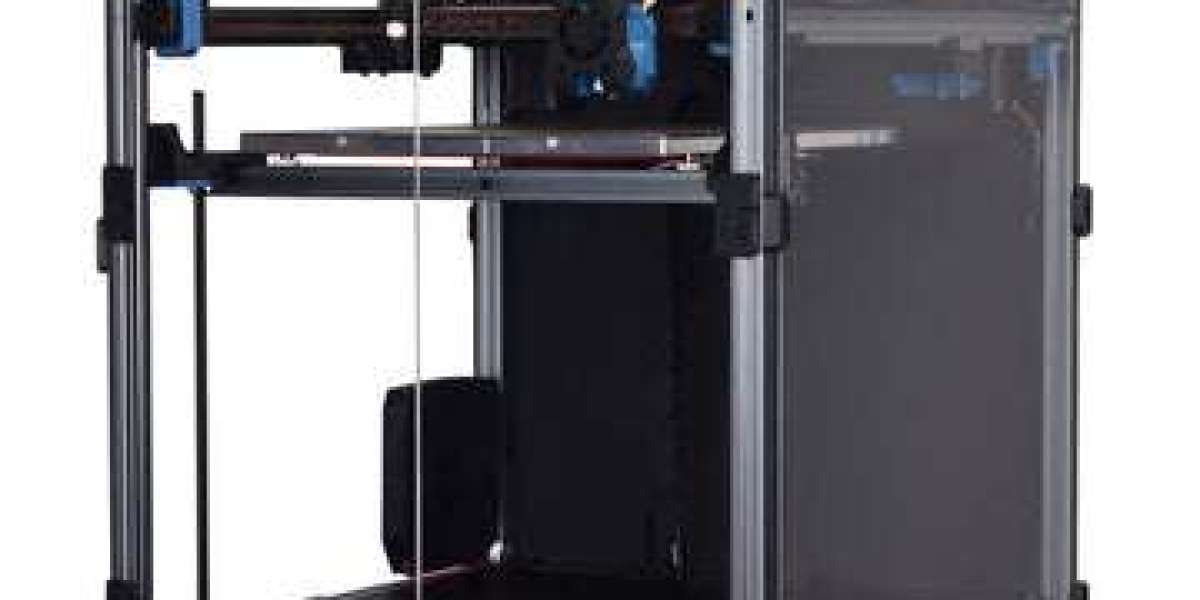

As 3D printing continues to evolve, innovation is key to unlocking new possibilities and pushing the boundaries of what is possible. The Voron LDO Kit, known for its precision and reliability, is at the forefront of this evolution with its commitment to continuous improvement and adaptation to emerging technologies. In this exploration, we delve into the future of 3D printing through the lens of Voron LDO Kit innovations, envisioning the advancements that will shape the industry in the years to come.

Integration of AI and Machine Learning

One of the most exciting prospects for the future of 3D printing is the integration of artificial intelligence (AI) and machine learning technologies into the printing process. Imagine a Voron LDO Kit equipped with AI algorithms that can analyze design files, optimize print settings in real-time, and anticipate and correct potential issues before they occur. With machine learning capabilities, the printer could learn from each print job, continuously improving its performance and efficiency over time.

Advanced Material Compatibility

As materials science advances, the range of printable materials available to 3D printers is expanding rapidly. The future of the Voron LDO Kit will likely see enhancements to its material compatibility, enabling users to print with a broader array of advanced materials, including biocompatible polymers, conductive filaments, and even materials with embedded electronics. By pushing the boundaries of material science, the Voron LDO Kit will empower users to create functional prototypes and end-use parts with unprecedented properties and capabilities.

Additive Manufacturing at Scale

While 3D printing has traditionally been associated with prototyping and small-scale production, the future holds the promise of additive manufacturing at scale. With advancements in automation, robotics, and additive manufacturing technologies, the Voron LDO Kit could play a pivotal role in the mass production of customized products, from automotive components to medical devices. By leveraging its precision and reliability, the Voron LDO Kit can contribute to the transformation of manufacturing processes, enabling on-demand production and reducing waste.

Seamless Integration with Digital Workflows

In the future, the Voron LDO Kit will likely be seamlessly integrated into digital workflows, providing a smooth transition from design to print. With enhanced connectivity and interoperability, users will be able to send print jobs directly from their design software to the printer, monitor progress remotely, and receive real-time feedback on print quality. By streamlining the printing process and eliminating manual intervention, the Voron LDO Kit will empower users to focus on innovation and creativity, rather than logistical challenges.

Conclusion

The future of 3D printing is bright, and the Voron LDO Kit is poised to lead the way with its commitment to innovation and excellence. From the integration of AI and machine learning to advancements in material compatibility, additive manufacturing at scale, and seamless integration with digital workflows, the Voron LDO Kit will continue to push the boundaries of what is possible in 3D printing. As the industry evolves and new technologies emerge, the Voron LDO Kit will remain at the forefront, empowering makers and enthusiasts to bring their visions to life with unparalleled precision and reliability.