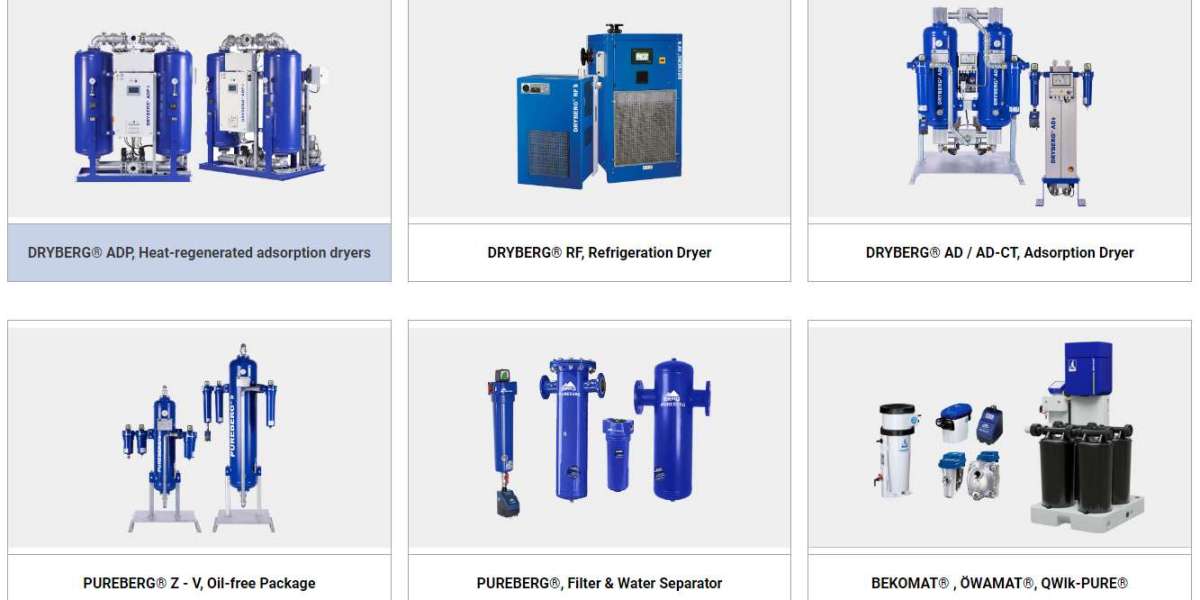

In industrial manufacturing and storage, maintaining clean and dry compressed air is essential for the integrity of processes and products. Compressed air dryers play a crucial role in achieving this, but proper filtration is equally important. This article explores the significance of proper filtration in compressed air dryers, including Adsorption air dryer, and its impact on industrial operations.

Removing Contaminants

Compressed air often contains contaminants such as oil, water, and particulate matter, which can adversely affect equipment performance and product quality. Proper filtration in compressed air dryer removes these contaminants, ensuring that the compressed air meets purity standards required for various industrial applications. By eliminating contaminants, filtration protects equipment from damage and prevents product contamination.

Extending Equipment Lifespan

Contaminants present in compressed air can cause premature wear and damage to pneumatic equipment, leading to costly repairs and downtime. Proper filtration helps extend the lifespan of equipment by reducing the risk of damage from contaminants. By maintaining clean and dry air, compressed air dryers with effective filtration systems contribute to the longevity and reliability of industrial machinery and tools.

Conclusion

Proper filtration is essential for compressed air dryers in industrial manufacturing and storage to maintain the purity and integrity of compressed air. By removing contaminants, filtration protects equipment from damage, prevents product contamination, and extends the lifespan of industrial machinery. As industries continue to rely on compressed air for various processes, investing in compressed air dryers with robust filtration systems becomes crucial for ensuring operational efficiency and product quality.