Bio-ethanol, a renewable fuel derived from biomass such as corn, sugarcane, or cellulosic materials, plays a vital role in reducing greenhouse gas emissions and promoting energy sustainability. The production cost of bio-ethanol encompasses various factors, ranging from feedstock procurement and processing to distribution and marketing. In this article, we will delve into the economics of Bio-Ethanol Production Cost and the factors influencing its cost.

Introduction to Bio-Ethanol Production

Bio-ethanol is produced through a fermentation process that converts sugars present in biomass feedstocks into alcohol. The most common feedstocks for bio-ethanol production include corn, sugarcane, wheat, barley, and lignocellulosic materials such as agricultural residues, forestry residues, and energy crops. The production process involves several stages, including feedstock preparation, enzymatic hydrolysis (for cellulosic feedstocks), fermentation, distillation, and dehydration.

Request For Free Sample: https://procurementresource.com/production-cost-report-store/bio-ethanol/request-sample

Factors Influencing Bio-Ethanol Production Cost

Several factors contribute to the production cost of bio-ethanol, including:

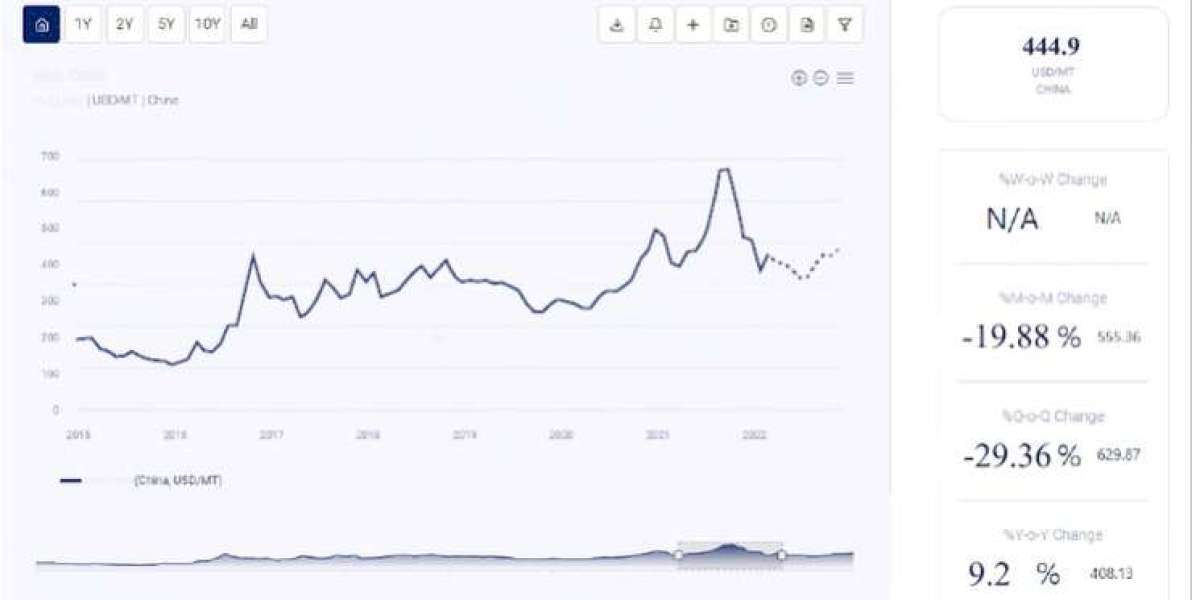

Feedstock Costs: The cost and availability of feedstocks significantly impact bio-ethanol production costs. Corn and sugarcane are among the most widely used feedstocks for ethanol production, with their prices influenced by factors such as agricultural yields, crop prices, weather conditions, and government subsidies.

Processing and Conversion Costs: The processing and conversion of feedstocks into ethanol involve various expenses, including enzymatic hydrolysis (for cellulosic feedstocks), fermentation, distillation, and dehydration. Costs associated with equipment, chemicals, enzymes, energy, and labor contribute to overall production costs.

Energy Consumption: The energy required for bio-ethanol production, including thermal energy for heating, electricity for mechanical operations, and steam for distillation and dehydration, represents a significant cost component. Energy efficiency improvements and optimization of process parameters can help reduce energy consumption and production costs.

Yield and Conversion Efficiency: The ethanol yield and conversion efficiency, defined as the amount of ethanol produced per unit of feedstock input, influence production costs. Improvements in fermentation technologies, enzyme efficiency, and bioprocessing techniques can enhance yield and conversion efficiency, thereby reducing production costs.

Co-Products and By-Products: Bio-ethanol production often yields co-products such as distillers' grains, corn gluten feed, and lignin, which can be sold or utilized as animal feed, fertilizer, or bioenergy feedstocks. The value of co-products and by-products offsets production costs and enhances the overall economics of ethanol production.

Market Outlook and Future Trends

The demand for bio-ethanol is expected to continue growing globally, driven by mandates for renewable fuel blending, environmental regulations, and efforts to reduce greenhouse gas emissions. Additionally, advancements in biotechnology, feedstock diversification, and process optimization are likely to improve the efficiency and economics of bio-ethanol production.

Furthermore, emerging technologies such as cellulosic ethanol production, waste-to-ethanol conversion, and integrated biorefinery concepts aim to utilize non-food feedstocks and maximize resource efficiency. Collaboration between industry stakeholders, government support, and investment in research and development are essential for advancing bio-ethanol production technologies and ensuring their competitiveness in the energy market.

Conclusion

In conclusion, the production cost of bio-ethanol is influenced by factors such as feedstock costs, processing and conversion costs, energy consumption, yield and conversion efficiency, and co-products and by-products. Understanding these factors and implementing cost-effective production practices are essential for bio-ethanol producers to remain competitive in the market while contributing to energy sustainability and environmental stewardship. As the bio-ethanol industry continues to evolve, innovation and adaptation to changing market dynamics will be crucial for its long-term viability and success.