In the fast-paced world of industrial machinery and equipment, maximizing efficiency is a priority. The performance of any industrial system hinges on the quality of its components, particularly its bearings. Roller bearings are one such crucial component that plays a significant role in ensuring the smooth and efficient operation of various machinery. This article explores why roller bearings are essential for industrial equipment and how providing customers with high-quality bearing products can contribute to enhanced productivity.

Understanding Roller Bearings and Their Importance

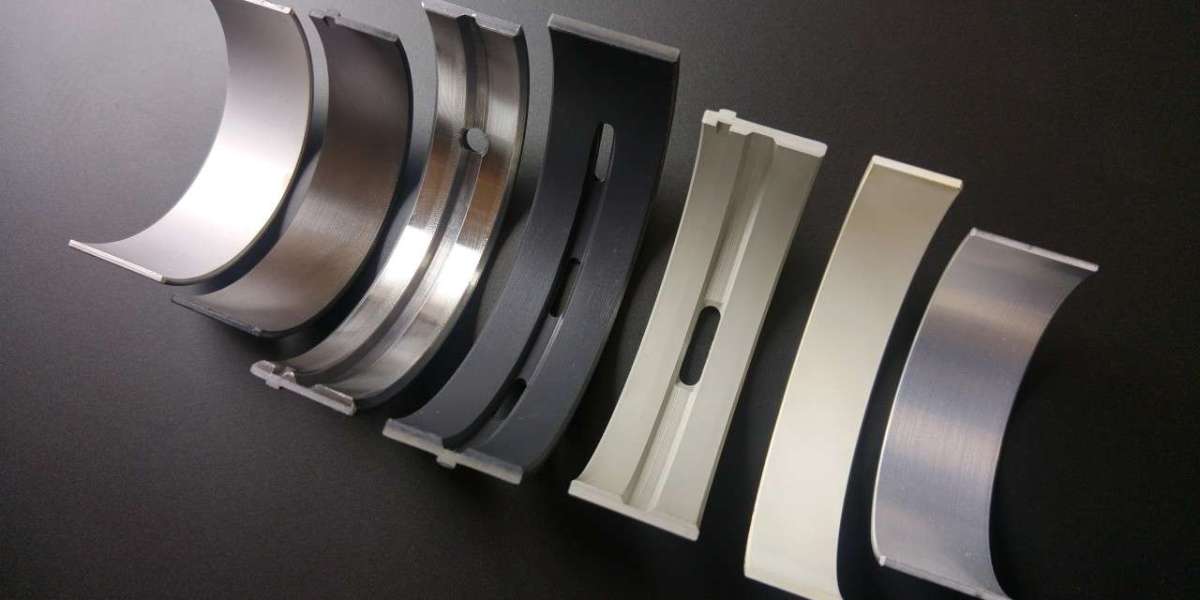

Roller bearings are cylindrical components designed to support loads and facilitate the movement of machinery by reducing friction between moving parts. They are known for their ability to handle heavy loads and withstand varying working conditions, making them a preferred choice across a wide range of industries.

Key Advantages of Roller Bearings

Load Bearing Capacity: Roller bearings are designed to endure substantial weight, making them suitable for use in heavy-duty industrial machinery.

Reduced Friction and Wear: Their precision design minimizes friction between moving parts, leading to less wear and tear on machinery components.

Improved Efficiency: By decreasing friction, roller bearings help enhance the efficiency of industrial equipment, resulting in better performance and reduced energy consumption.

Long Service Life: High-quality roller bearings are built to last, providing reliable service over extended periods and reducing the need for frequent replacements.

Providing High-Quality Bearing Products

To meet the diverse needs of customers across industries, offering high-quality bearing products is essential. Advanced manufacturing processes and the use of high-quality materials are key to ensuring roller bearings operate stably under different working conditions. By focusing on precision design, manufacturers can provide products that minimize friction, enhance efficiency, and extend the service life of industrial equipment.

Conclusion

Roller bearings are a fundamental component of industrial equipment, enabling machinery to perform optimally and efficiently. Offering high-quality bearing products not only enhances productivity but also ensures the longevity and reliability of equipment across various industries. By prioritizing quality and precision in the design and manufacture of roller bearing, manufacturers can support the diverse needs of their customers and contribute to the success of their operations.